O Gauge Modelling on the GWR

A personal Journey

5 ton Hand crane truck from METEOR MODELS

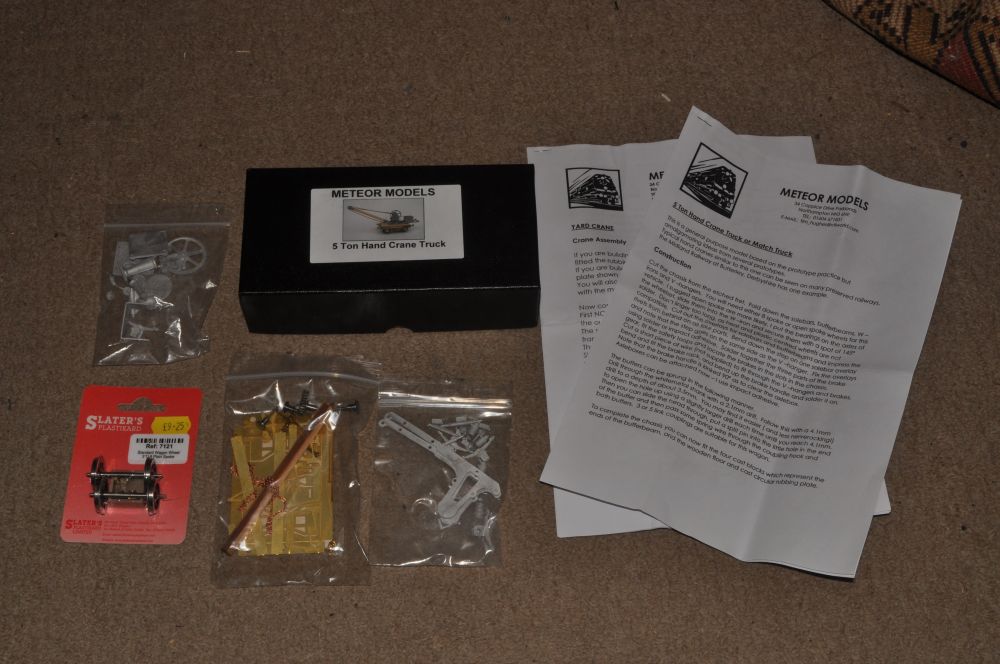

This is what you get in the nice Meteor Models box as supplied. Two sets of instructions, (one for the crane the other for the match truck). 3 plastic bags containing brass parts to make up the match truck, and two containing white metal parts to make up the crane. I purchased the wheels separately as they are not included. Although each is separate I thought it best to start from the bottom and work up so the match truck is the first part to be constructed.

Remove the fret carefully from its bag. Its folded and the thin brass pieces easily puncture the bag and get caught, bending them in the process.

The chassis is in one piece and requires the sides and ends to be bent at right angles. You will need bending irons of some description as the chassis is quite thick and will distort. I bent the bufferbeams first and then the sides. You also need to bend down the W irons and the V hanger. Check the bearing holes with a wheel bearing first as they may need fettling to remove burr.

Ieft the bushes free running at the moment. Then proceeded to firstly pres out the rivets and then solder the overlays for the buffer beams and sides in place. Also the brake gear laminate, (I used only two of the three supplied), was soldered in place and checked so as not to foul the wheels.

The safety straps and rodding have been put in place. I put the step on the opposite side to the brake lever, it seemed to be more logical to have it there. The axle boxes have also been glued in place having bored out the bearing holes so they could sit flush with the 'w' irons.

I'm not a big fan of his buffers shanks. You have to drill the shanks out first to the thread size and then to the piston size. The clearances for the piton parts of the buffers are pretty tight and due to the amount of heat generated when drilling it makes this an almost impossible operation as the chamber is liable to collapse. Therefore, I have ordered a set of FO11s from Invertrain that come setup and only require fitting and all for £6.75. More on that when they arrive.

A nice touch is the decking though. As shown here and simply glued to the top of the match truck. The kit comes with two different sorts of supports and the one to use if the crane is mounted on this truck is the one shown in the picture.

The crane is fairly straightforward to make up. I soldered the lower bars on one side and squared them up first. then put the other side on and soldered that. it is possible to make the gearing work to raise and lower the chain but I chose to have it fixed as it is al in white metal and would wear away quickly. The wheels for the weighting box are really small and I used other parts from the bits box which were slightly larger and less fragile looking. Painting is not easy as the wheels are close up to the framework but is there another way?