My O Gauge Journal on

Modelling the GWR

A personal Journey

A dry run

using the transfers

Do a dry one piece run first. This was key for me in successfully

applying transfers. None of these transfers will be applied as one

piece. That was my downfall on previous attempts and had resulted in

a waste of time and money and only useful if you suffer from low

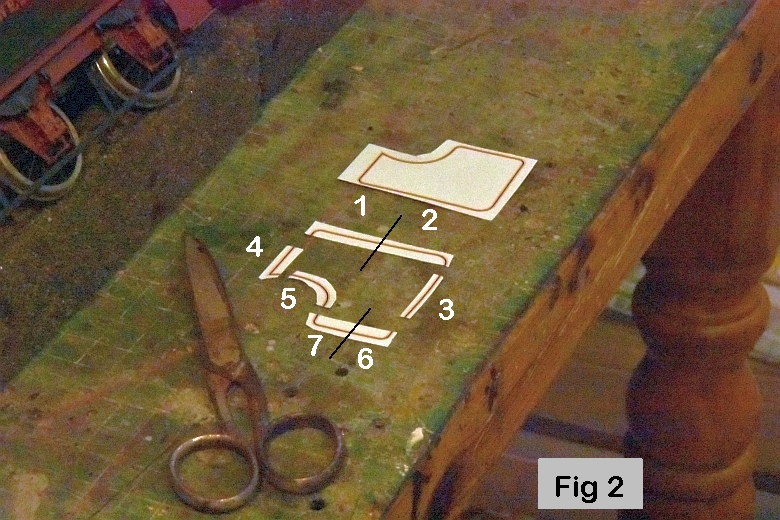

blood pressure! They are to be cut up into small sections as shown

in Fig 2 and each section is to be applied separately in a

predetermined order. How they are cut up is therefore important and

you should choose the way that makes their application the easiest.

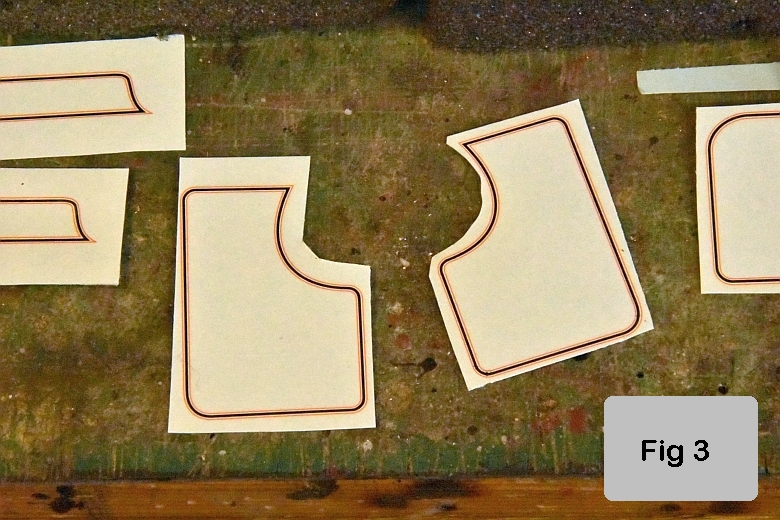

So start initially with it in one piece, (fig 3) and match the

transfer against the area it is to fit in. Often space is tight or

needs the transfer to lose a few mms along its straight edges. Doing

this will help you assess what needs to be done. As shown here in

Fig 2, to accommodate the cab sides I had to split the side pieces

into 1 and 2 and 6 and 7 to reduce their lengths on the cab sides.

The dry run determines how you will do that.

Apart from checking sizes, you also need to be aware of

potential obstructions so take your time to see how a piece will fit

first, again as a dry run. Obstructions like pipes and handrails and

even rivets you have to thread the transfer under or over will add

to your success rating. A particular piece of transfer may also have

to be cut itself to avoid a larger protrusion on the boiler. When

you are satisfied, cut up the transfer into workable pieces and work

out the order in which you will apply those pieces. Leave a small

area of backing paper around the transfer so that you can use it to

manipulate the transfer later. Test all that out before using the

water bath. Then put one piece at a time into the water bath when

you are ready to apply it to the loco body.